An Advanced Sealing Material for Current Innovative Machinery

In our contemporary 21st-century constantly evolving world governed by stricter government regulations, energy saving, efficient use of resources and sustainability are the norm. This is strikingly noticeable in our daily life and in various industrial sectors with novel products such as pumps, compressors, valves and gearboxes, embodying progress in construction design and composition. In particular, lightweight mechanical systems envisioned for sparing energy call upon new building materials, and “cover-and-pot” systems are a pertinent example of this trend.

The housing (cover-and-pot) of mechanical machinery if made from diverse panoply of metals (e.g. cast iron, aluminum, aluminum‒magnesium alloys) are prone to deformation under coupled temperature and mechanical forces. This forces designers to attenuate this effect e.g. by incorporating reinforcements in the construction.

For example, “cover-and-pot” construction systems suffer from the following:

- deficient stiffness of the cover and/or housing

- broad spacing between the adjacent connection bolts especially in complex housing geometries

- low allowable bolting force.

Due to these problems a non-uniform and inadequate surface pressure on the gasket results, leading inevitably to leakage during either the assembly or operation. Despite the progress in constructions adaptation in view to circumvent such weak-points or flaws, the necessity to hermetically seal the system especially at the cover level remains.

The solution

Our solution to these problems is TESNIT® BA-SOFT, an exemplary advanced highly compressible fiber-based gasket material which was specially formulated at DONIT to match the modern mechanical applications’ requirements; these wherein adaptability to the assembly connection-surfaces deformities or defects is allied to a sufficient thermo-mechanical performance.

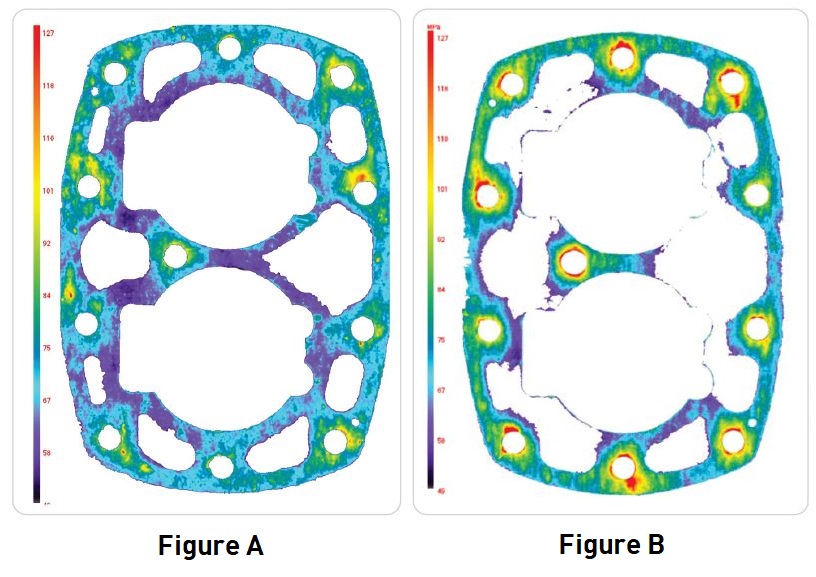

Gasket surface pressure distribution visualized by the Fujifilm test (see the image below) under identical loading on gaskets cut from TESNIT® BA-SOFT (A) and a common standard fiber-based material (B). (A) is advantageous vs. (B) displaying a good full contact (i.e. a tight seal) across all the required contact area including the central one.

TESNIT® BA-SOFT gasket material fits perfectly the bill of machinery for various types of industry; it is reliable and guarantees their safe operation.